Casting & Hot Mills

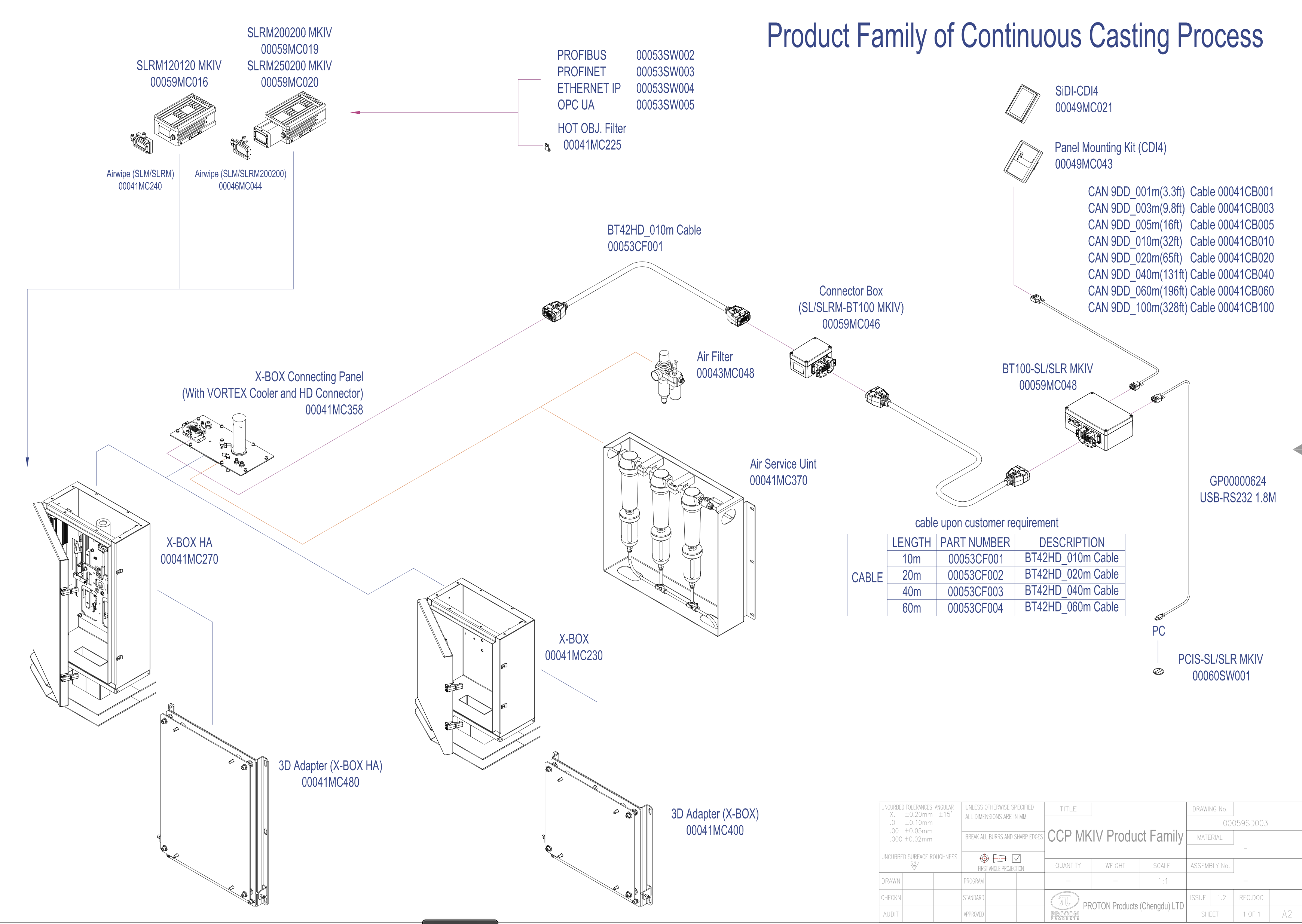

Hot Rolling Mills and Continuous Casting Applications require a robust solution to protect the InteliSENS SLR-M Series gauge head from Extreme Temperatures. Our Long Stand-off Gauges with Zero Speed, Material Present, and X-Box Protective Enclosures are perfect in these environments. Field-proven to provide reliable speed and length measurement directly to the PLC. With Non-Contact, there is zero slippage and zero wear, increasing your plant uptime and your cut length accuracy.

InteliSENS® SLR - M SeriesCold Rolling Mills

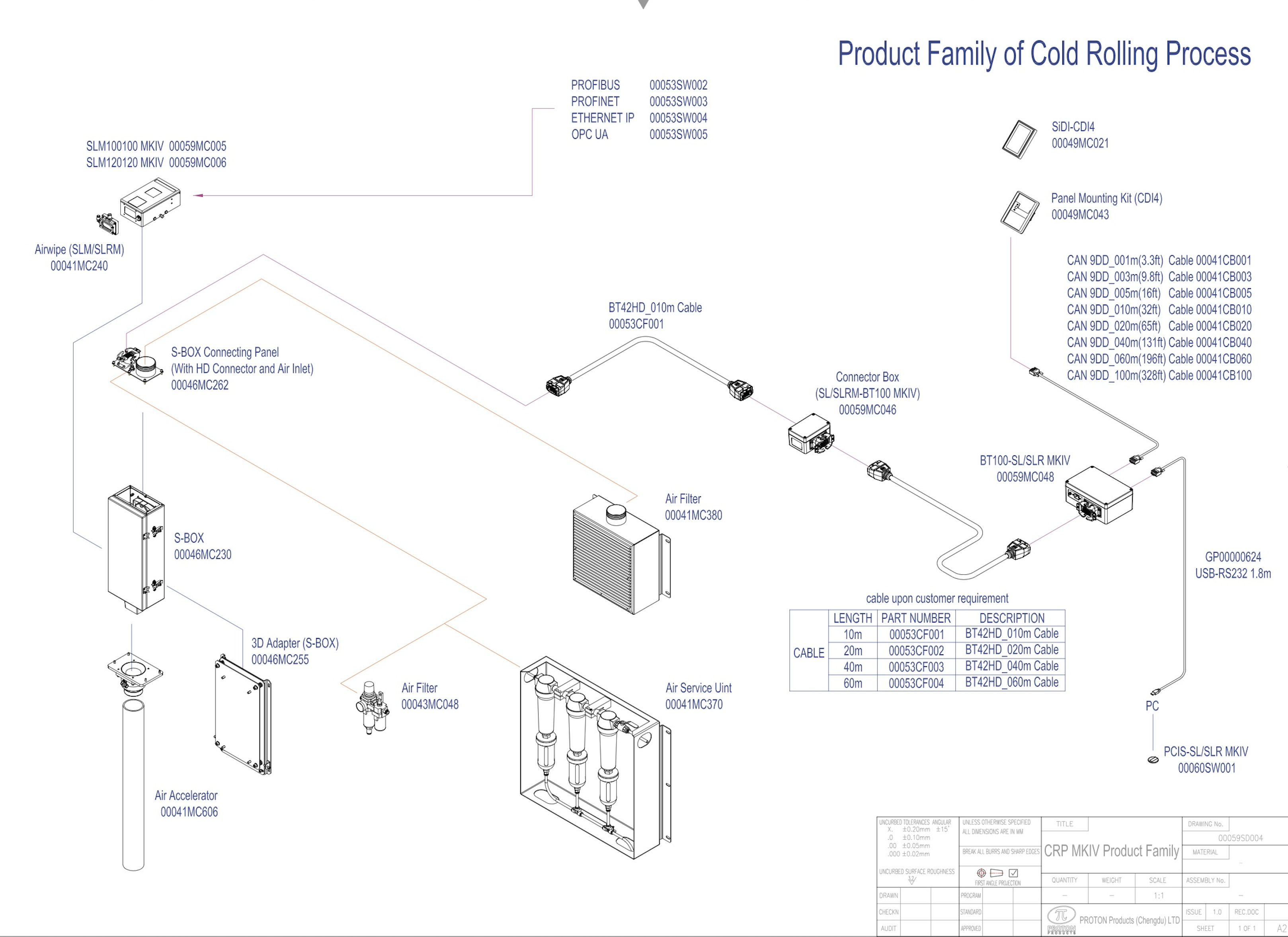

Cold Rolling Mill Applications require a robust solution that can endure atmospheres

containing High Temperatures, Steam, and Cooling Liquid Spray. Our InteliSENS SL-M

Series Long Stand-off Gauges and X-Box Protective Enclosure with Air and Water Cooling along with Positive Pressure Purging is field-proven to provide reliable speed and lengthvmeasurement directly to the PLC. With Non-Contact, there is zero slippage and zero wear, increasing your plant uptime and your AGC results.

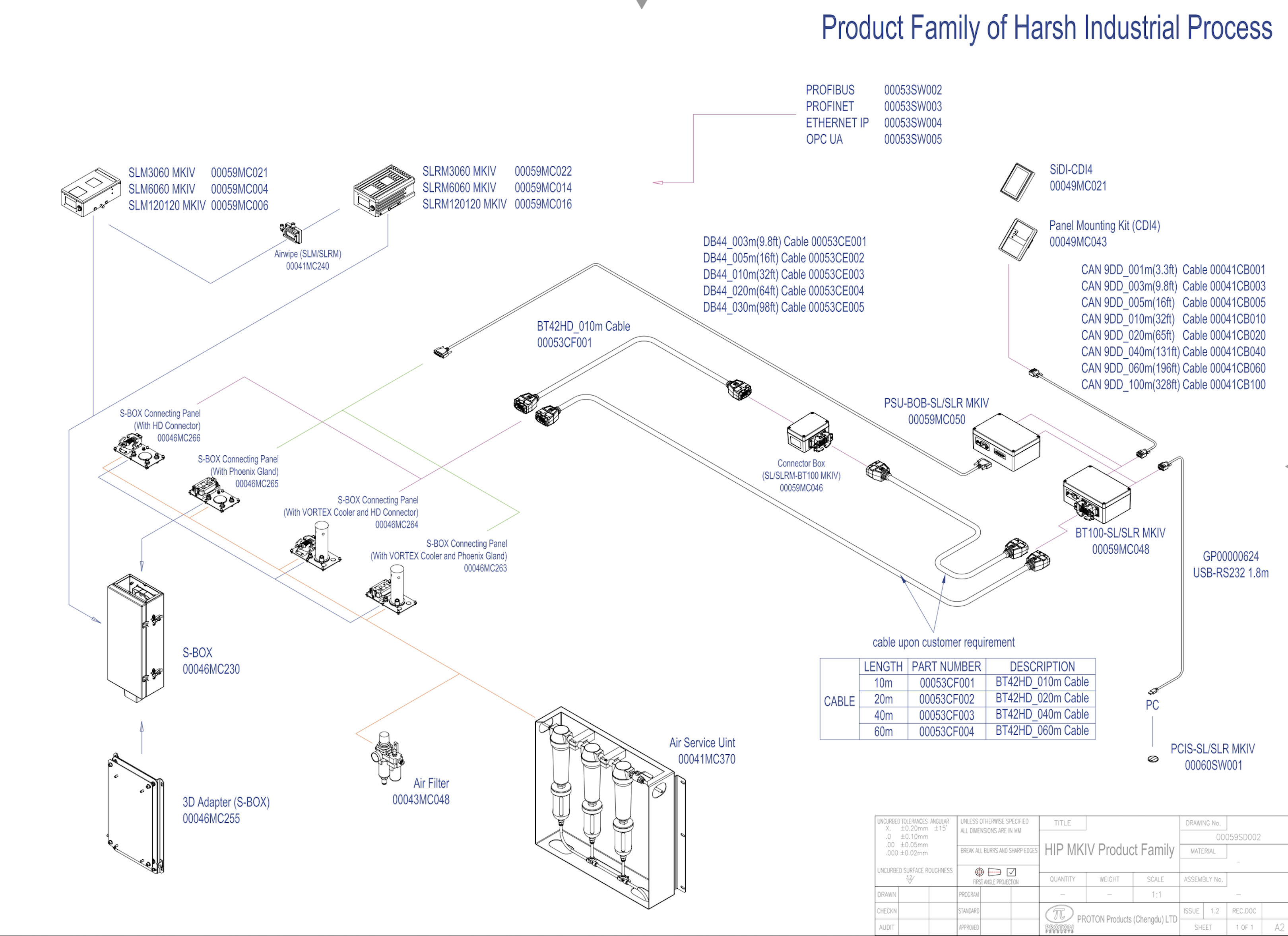

Bar, Tube & Pipe Mills

Bar and Tube Mill Applications can be tough environments and often require a protective enclosure. The InteliSENS SL-M Series gauge head with a Medium to Long Standoff, with or without an H-Box Protective Enclosure is field-proven to provide reliable speed and length measurement to your PLC or as a stand-alone device. With Non-Contact, there is zero slippage and zero wear, increasing your plant uptime and cut to length accuracy.

InteliSENS® SL - M SeriesProcess Lines & General Applications

Bar and Tube Mill Applications can be tough environments and often require a protective enclosure. The InteliSENS SL-M Series gauge head with a Medium to Long Standoff, with or without an H-Box Protective Enclosure is field-proven to provide reliable speed and length measurement to your PLC or as a stand-alone device. With Non-Contact, there is zero slippage and zero wear, increasing your plant uptime and cut to length accuracy.

InteliSENS® SL - M Series