Quality control plays a crucial role in any manufacturing industry, ensuring optimal functionality and efficiency. Among the most crucial components of quality control, ensuring the correct diameter of products and materials stands paramount. This is where diameter gauges come into play. Renowned manufacturer Proton Products Inc. has distinguished itself as a reliable provider of diameter laser gauges, offering an advanced solution for this vital need in the manufacturing industry.

The Importance of Diameter Gauges in Manufacturing

Diameter gauges are critical tools for ensuring product uniformity, performance, and adherence to specifications. They are designed to accurately measure the diameter of various items in the production process, including wires, pipes, cables, and more. The need for precision in these measurements cannot be overstated – even the slightest deviation can lead to operational inefficiencies, increased costs, and lower product quality.

Proton Products Inc. – Redefining Precision

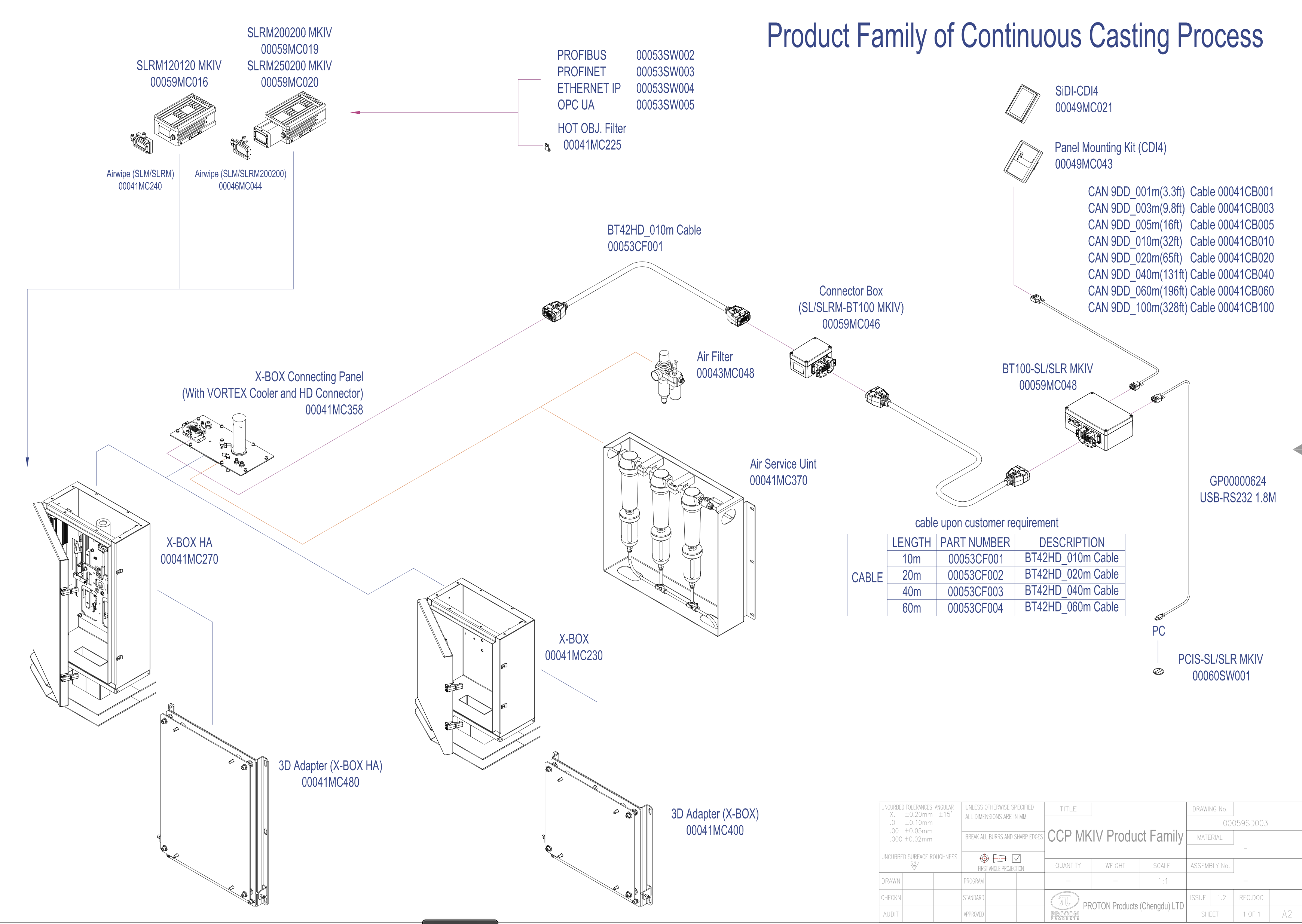

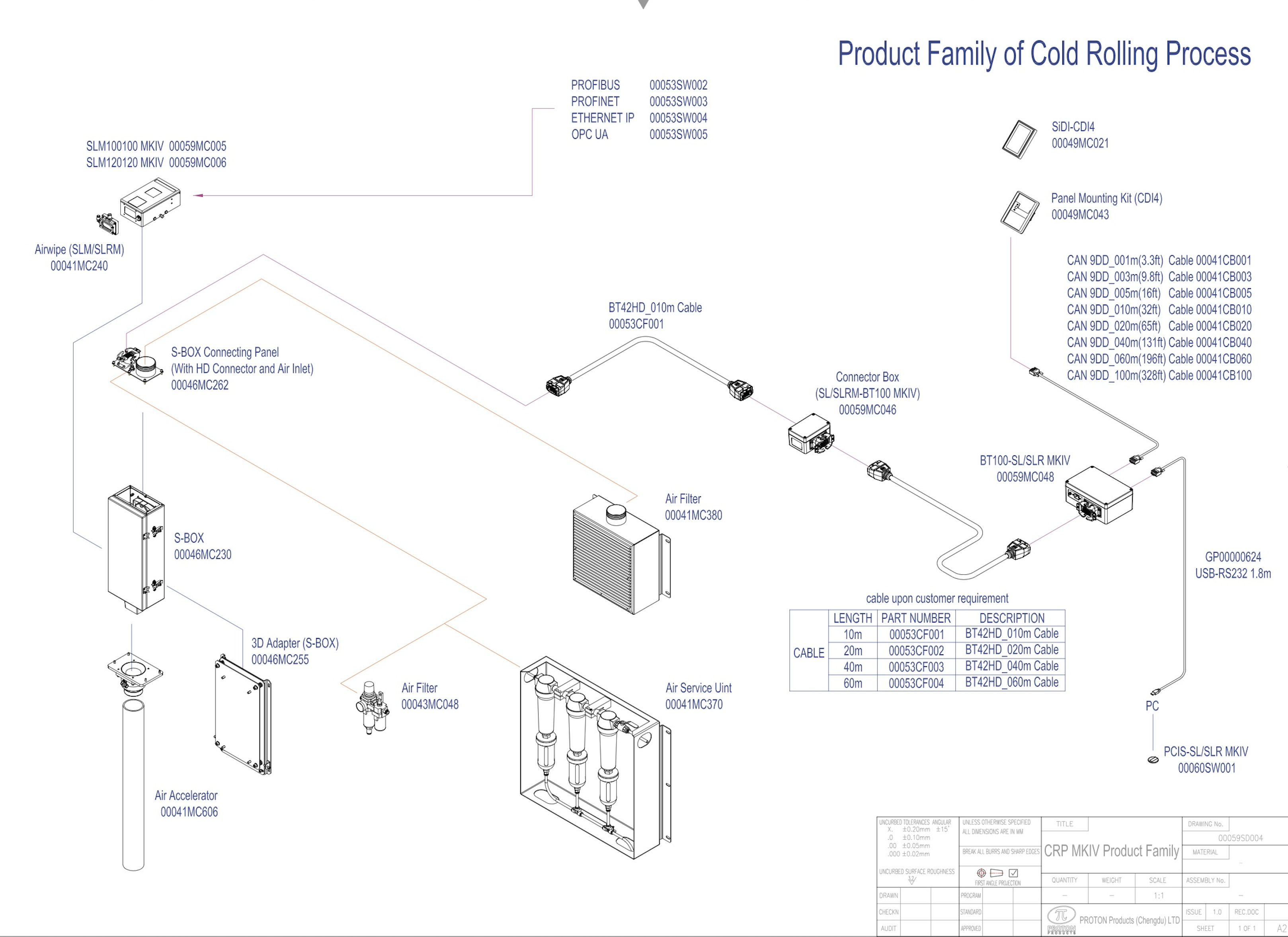

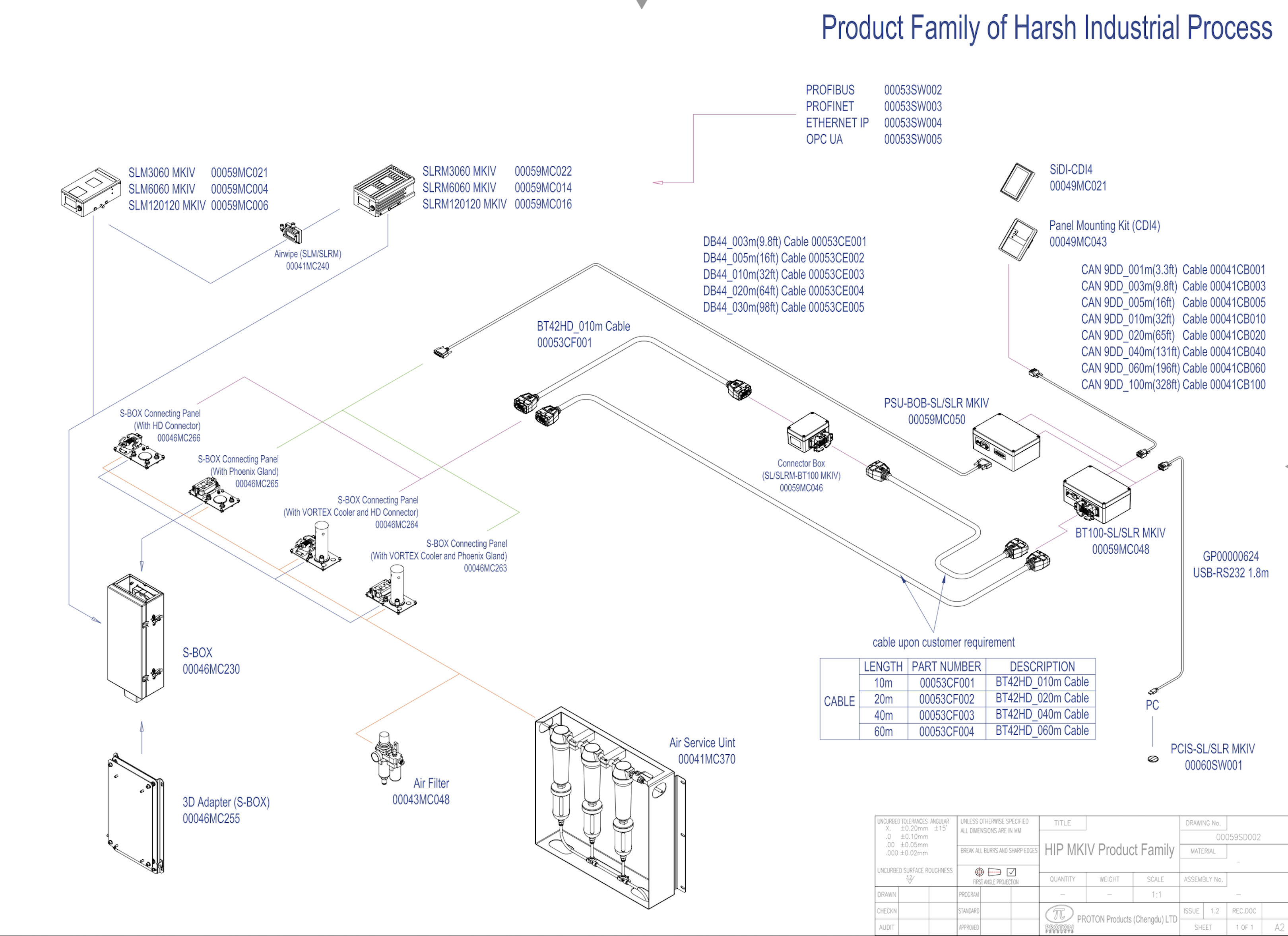

Proton Products Inc., a globally recognized name in the manufacturing industry, delivers high-precision diameter laser gauges, enhancing operational efficiency and product consistency. Their advanced laser-based technology gives manufacturing companies an edge by ensuring precise measurements, thereby reducing errors and wastage in production.

Proton Products’ diameter gauges employ non-contact laser scanning technology, which accurately measures diameters in real-time, irrespective of product speed or vibration. This ensures a high degree of accuracy and repeatability, guaranteeing consistent quality and adherence to industry specifications.

Diameter Gauges – A Vital Tool for Many Industries

The utility of diameter gauges extends across a multitude of industries, including but not limited to:

1. Wire and Cable Manufacturing: Diameter gauges play a vital role in ensuring that wires and cables meet the required specifications for various applications, including telecommunications, power transmission, and automotive applications.

2. Pipe and Tube Manufacturing: In the manufacture of pipes and tubes, diameter gauges are indispensable. They ensure that the final product meets the required dimensional tolerances, thereby guaranteeing its fitness for purpose.

3. Automotive Industry: With the intricate and detailed nature of automotive components, the role of diameter gauges in maintaining quality control is essential.

The Proton Products Advantage

Choosing Proton Products’ diameter gauges ensures optimal accuracy and performance. The company’s commitment to innovation, backed by its robust after-sales support, establishes it as a go-to solution for diameter measurement needs.

Proton Products’ diameter gauges are designed for ease of integration into production lines, minimizing downtime and maximizing efficiency. The company’s solutions are developed with user-friendly interfaces that facilitate easy calibration, ensuring seamless operation and consistent results.

By using Proton Products Inc.’s diameter laser gauges, manufacturers can reap numerous benefits, including improved product consistency, reduced waste, increased production speed, and improved customer satisfaction.

Conclusion

With the ever-increasing demand for precision and consistency in manufacturing, the role of diameter gauges is more crucial than ever. Proton Products Inc., with its state-of-the-art diameter laser gauges, offers a solution that caters to this need, providing manufacturers with an indispensable tool for quality control. By choosing Proton Products Inc., businesses ensure they are investing in a reliable, efficient, and advanced solution that keeps them at the forefront of their industry.

Choosing the right tools for quality control in manufacturing, such as Proton Products’ diameter laser gauges, can significantly impact the bottom line. Remember, the value of precision in manufacturing cannot be overstated – the right tool can make all the difference.