Accuracy and precision are paramount when it comes to gauging speed and length in manufacturing processes. The choice of tool can make a significant difference in achieving optimal results. While roller wheel gauges have traditionally been used for these measurements, laser gauges, such as those produced by Proton Products Inc., offer improved accuracy, efficiency, and reliability.

The Era of Roller Wheel Gauges

Roller wheel gauges have long served as the go-to instrument for speed and length measurement in various industries. These devices work by physically making contact with the material whose length or speed is being measured. As the material moves, the roller wheel turns, and the rotations are counted to determine length or speed.

However, the roller wheel gauges have a set of inherent challenges, including:

1. Contact Measurement: These gauges make direct contact with the product, which can potentially cause damage or marking, especially on delicate materials.

2. Wear and Tear: Over time, the roller wheels wear down, causing their diameter to decrease. This change in diameter leads to inaccurate measurements.

3. Slippage: The roller wheel gauges are susceptible to slippage, especially when dealing with smoother materials. This slippage further compromises the accuracy of the measurements.

Transitioning to Laser Gauges

Enter laser gauges, such as those manufactured by Proton Products Inc. Laser gauges are non-contact measurement tools that use advanced laser technology to measure speed and length. They offer a myriad of advantages over the traditional roller wheel gauges:

1. Non-Contact Measurement: Laser gauges eliminate the potential for damage or marking to the product as there is no physical contact.

2. High Accuracy: Laser gauges provide highly accurate measurements due to their sophisticated technology, enabling improved product quality.

3. No Slippage: As they operate without contact, laser gauges are not subject to slippage, which contributes to their superior accuracy.

4. No Wear and Tear: Laser gauges remain accurate over their lifetime as they have no moving parts that can wear out or degrade.

Proton Products Inc.: Leading the Charge in Laser Gauges

Proton Products Inc. has established itself as a leader in the production of high-quality laser gauges. Its speed and length laser gauges deliver superior precision and reliability compared to traditional roller wheel gauges.

Proton’s laser gauges utilize advanced laser Doppler technology to measure the speed and length of moving products accurately. Their intuitive design and user-friendly interface make them easily integrated into existing production lines. They are robust and require minimal maintenance, ensuring they remain operational over extended periods and increasing overall productivity.

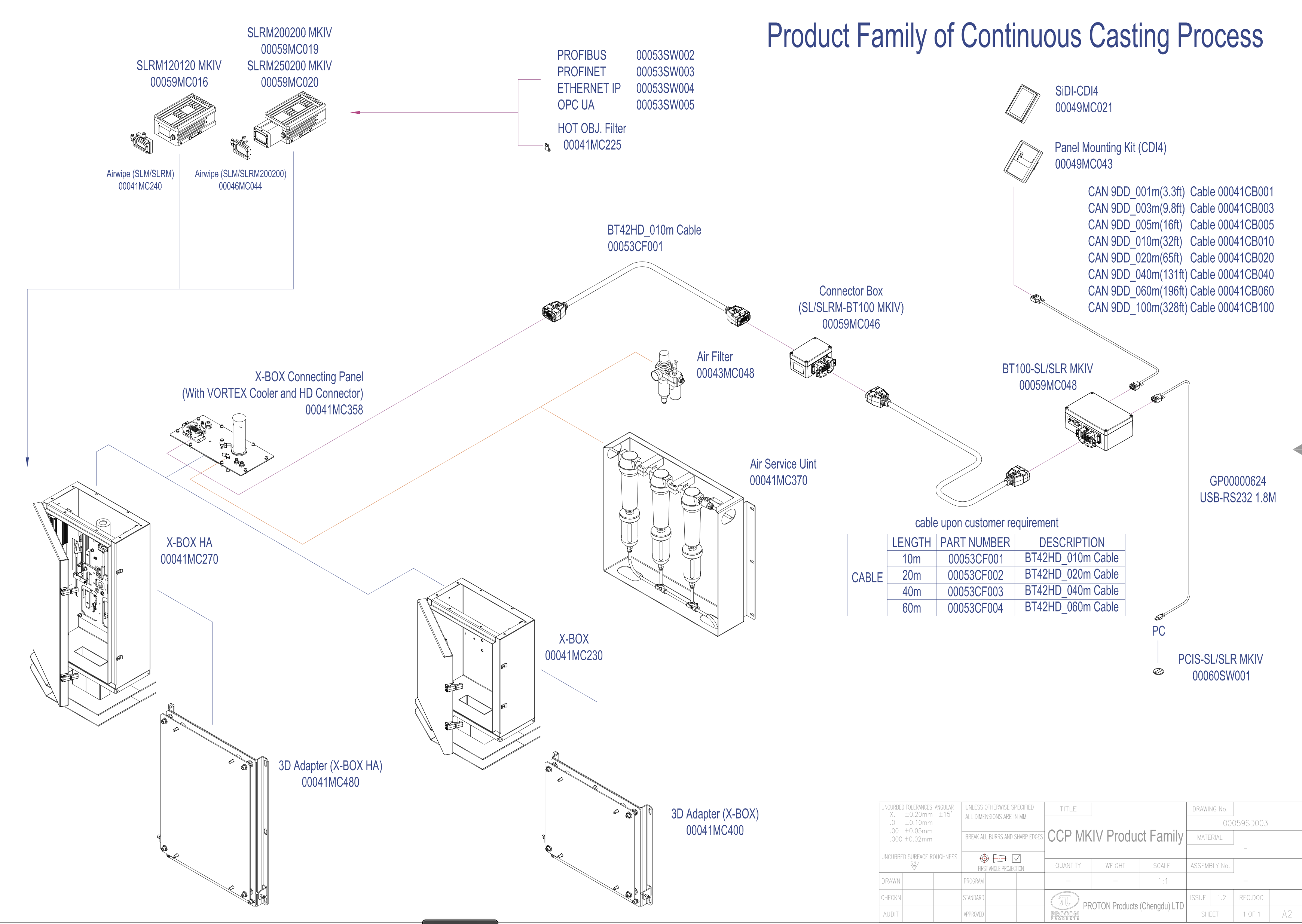

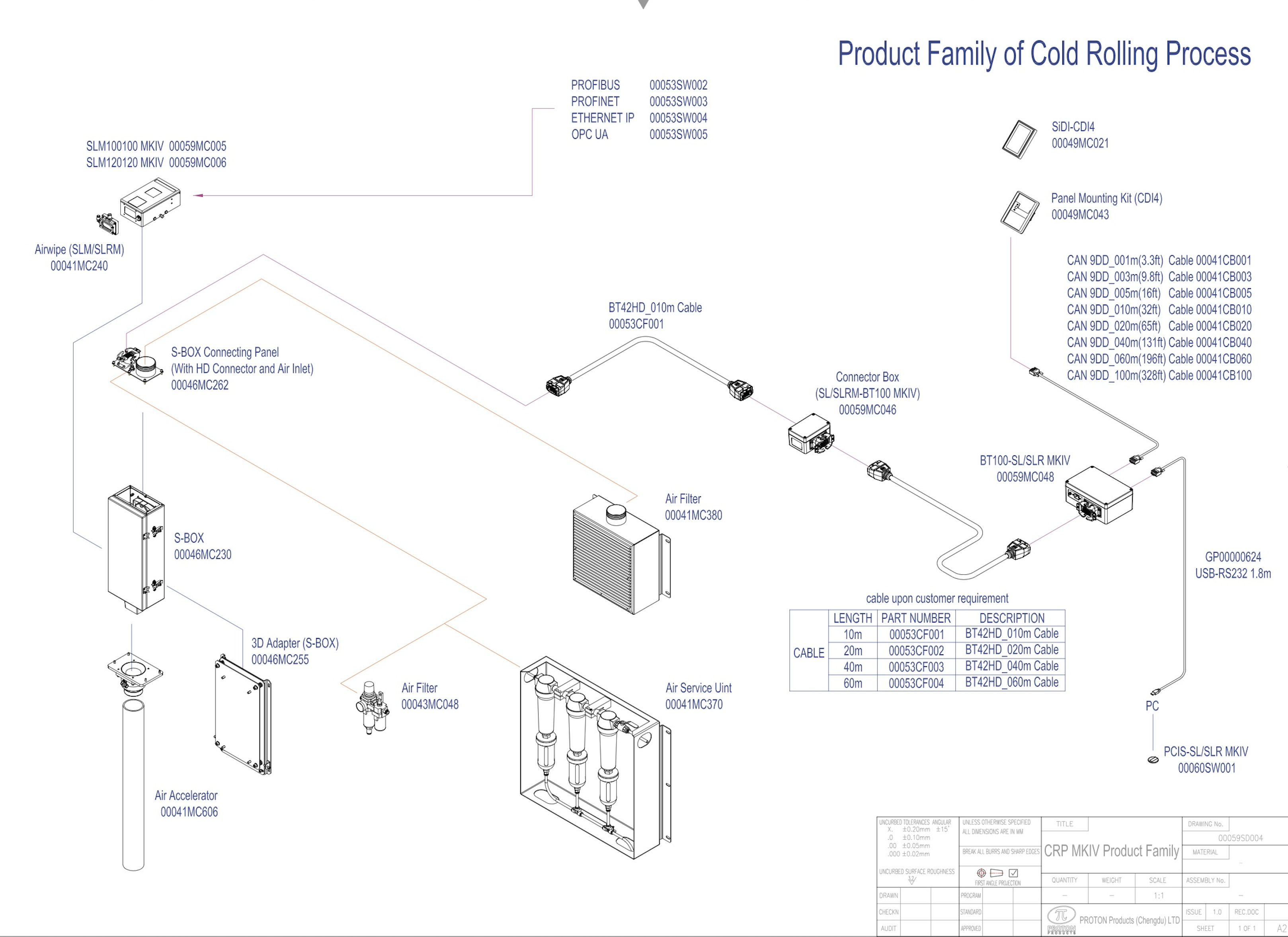

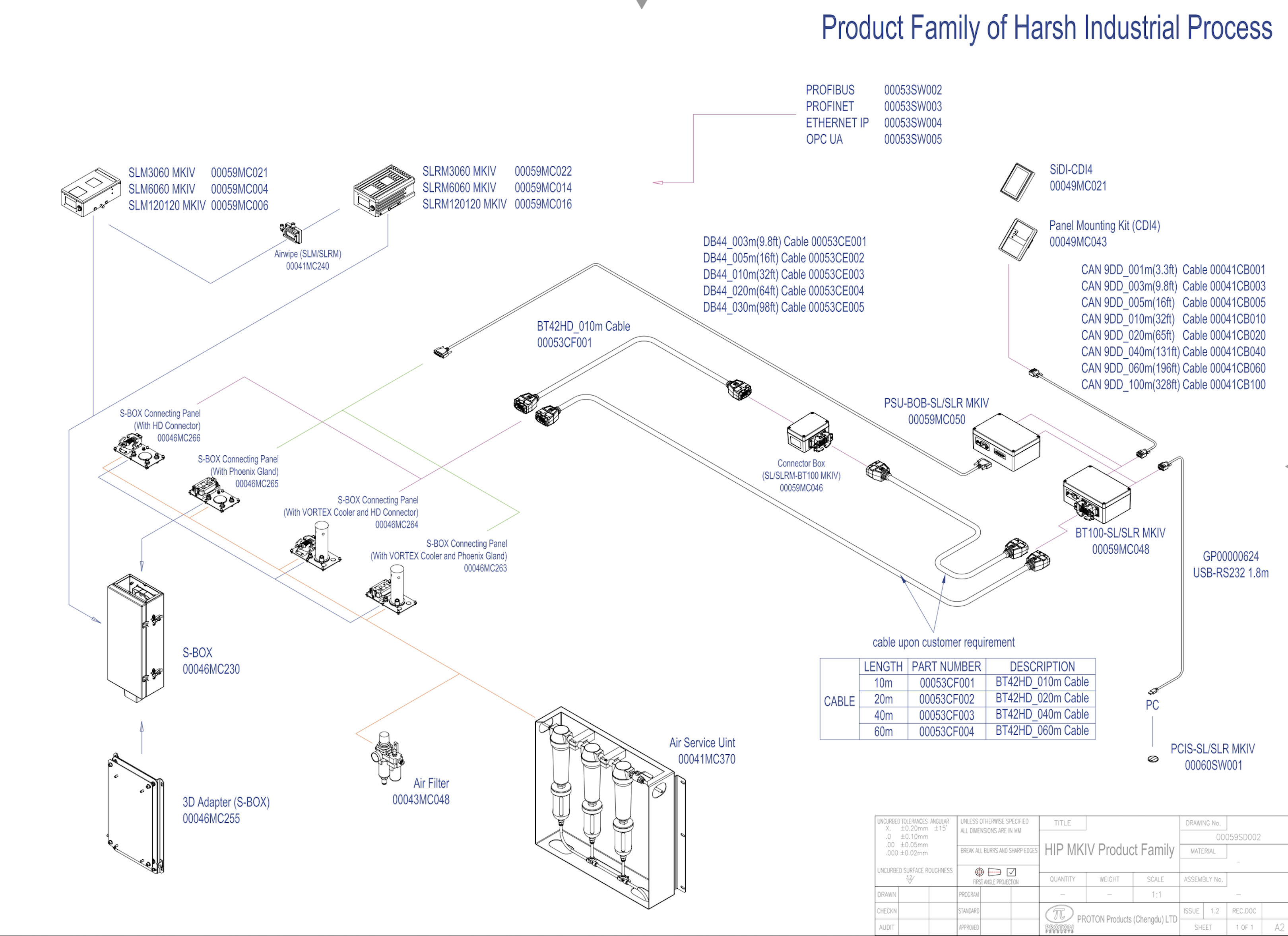

Proton Products Inc.’s laser gauges have found application across a wide range of industries, including wire and cable manufacturing, extrusion processes, and the production of tubes and pipes. By utilizing these advanced gauges, manufacturers can assure their products’ dimensional consistency and enhance the overall production quality.

Conclusion

In an era where accuracy and precision are more critical than ever, the transition from traditional roller wheel gauges to advanced laser gauges is a step towards better quality control. With their superior precision, non-contact measurement, and robustness, laser gauges, such as those produced by Proton Products Inc., represent the future of speed and length measurement in manufacturing.

By investing in laser gauges, businesses can significantly improve their manufacturing processes, ensuring the production of consistent, high-quality products. As a trusted name in the industry, Proton Products Inc. continues to deliver solutions that drive innovation, efficiency, and accuracy in the world of manufacturing.